Question

It is often suggested that I use low-noise cables when incorporating piezoelectric (PE) accelerometers into my test setup. Why is this? What exactly is a low-noise cable and how does it compare with other types of instrument cables available on the market?

Answer

"Low-noise" has become a commonly used label within the global testing community to describe the type of cable technology most widely used with piezoelectric accelerometers, though the terminology itself is actually a misnomer. A more accurate characterization would be "noise treated" cables. Of course, the ultimate testing goal is for all instrument cable to be "low noise", allowing the test engineer or technician to make accurate measurements without signal interference from the cabling itself, the exact source of which can be very difficult to diagnose.

"Noise treated" is a more accurate term than "low noise." Typically, a cable manufacturer has modified the cable in some fashion to make it perform better when used with a piezoelectric (PE) accelerometer and charge amplifier system. This is what sets it apart from regular instrument cabling. Regular cable that has not been treated for noise tends to generate excessive internal charge when disturbed or vibrated.

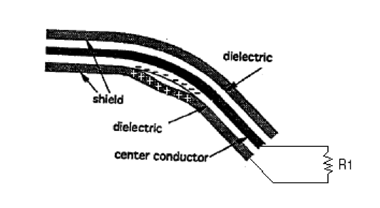

A common example of this can be seen when two plastic sheets are stuck together, then rapidly pulled apart. An electrostatic discharge is generated across the surface of the sheets that one can actually feel (this is also called static electricity). The same phenomenon occurs when a cable is disturbed. As the cable is bending, small separations between the constructed cable layers occur (e.g., between outer jacket and braided shield, as shown in Figure 1).

Figure 1

Just as when two plastic sheets are separated, a charge is generated, the same occurs within cables, and is known as the so-called triboelectric effect. The charge amplifier at the end of the cable, whose function is to convert charge to voltage, has no way of separating this charge from the legitimate charge output, or measurement signal, originating from the accelerometer. And because the piezoelectric accelerometer, cable and charge amplifier combination forms a high impedance circuit, there is no place for this charge to go, so the amplifier converts it to voltage. An error signal (or noise) is thus generated, which can ultimately affect measurement integrity and testing results, and lead to costly troubleshooting and unforeseen downtime.

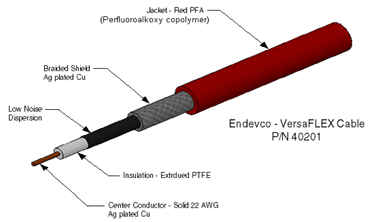

The proper noise treatment of cables offers a means of helping to solve this problem. Since the charge is generated by a separation of cable layers, a conductive dispersion material is added between cable layers, as shown in Figure 2. This dispersion material acts to reduce the generation of the triboelectric charge. It does not completely eliminate it, but it can reduce the charge significantly.

Figure 2

To ensure the highest possible quality "low-noise" cables for use with our piezoelectric sensors and instrumentation, Endevco has implemented a highly unique cable quality assurance program. The entire length of every spool of noise treated cable we manufacture is tested for "low-noise" characteristics prior to sale and shipment to the end customer. As part of this process, spools of cable are fed through a specially constructed machine and are vibrated when transferred from one spool to another. As each spool is fed through the machine, the resultant cable charge output is closely monitored. If any section of the spool exceeds a strict noise specification, that section is identified, cut out and rejected. This is our assurance to you that any "low noise cable" assembly we ship will meet your highest expectations - and ours.